Most everyone who adopts an old Honda CT90 at some point gets to where the bike won’t start and your first instinct is to start making random adjustments, but no matter how many times you adjust or clean everything the bike just won’t start. After doing this a number of times myself I now try and take a more methodical approach where I follow the sequence of steps I have outlined below, and I’m usually successful at getting the bike running again.

Others may take a different approach, but I thought I would share the items I look at and the order I look at them in case this information is useful to someone else dealing with trying to get a CT90 to start.

Step 1 – Do you have good compression?

Fundamental to getting a bike running is having a reasonable amount of compression, and the more you have the better. If you have a compression gauge put it on and see what you have, but if you have greater then 80 psi that should be adequate to start the bike.

If you don’t have a compression gauge you still can get a good sense of the level of compression you have by the amount of resistance you get when you kick the bike over. If there is a nice definite peak resistance that builds up and requires some force to get through then your probably ok.

If your bike kicks over with little resistance then your next step is to adjust your valves and hope your lack of compression is due to a misadjusted valve and not a problem with the rings on your piston. When you adjust your valves make sure you have at least .002 clearance and a hair more won’t hurt. If I don’t have a feeler gauge handy I just turn down the adjustment screw on each valve until it just kisses the top of the valve stem and then back it off 1/8 of a turn and tighten the lock nut. Based on the pitch of the thread on the adjustment screw this will give you about .0025 inch clearance.

If after adjusting your valves it seems like your compression improved then you’re on the right path to getting your bike started.

If you have faith that your valves are adjusted correctly and your piston and rings are good, but your kick starter feels kind of mushy, then there is a good chance your clutch is slipping. Slipping clutches don’t somehow heal themselves, so while it may be good enough to start your bike once in a while its only going to get worse and its time to rebuild your clutch.

Step 2 – Is your timing chain and gear installed correctly?

While this generally isn’t a problem if your bike was running previously and you haven’t disassembled your top end, but if you just picked up a new project or had just refreshed your top end it doesn’t hurt to go back and check to make sure the timing gear and chain were installed correctly.

I go into detail on how to correctly install the timing chain and gear in the post at the link below:

The Basic Sequence and Process to Set or Adjust your CT90 Timing

But the readers’ digests version is that when the crank is at Top Dead Center (and not the F fire position) like is shown in the picture below then the “O” mark on the timing gear in the head needs to be aligned with the notch in the head like is shown in the following picture.

Step 3 – Is the spark advancer assembled correctly?

Step 3 – Is the spark advancer assembled correctly?

Since you had to remove the spark advancer to check to see if the timing gear was installed correctly, this is the time to make sure the cam on the spark advancer is installed correctly. A very common problem is that people install the cam 180 degrees out from its correct position because the it can be installed two ways and people don’t pay attention and make sure and align the marks on the cam and base assembly when putting it back together after it may have been pulled apart to clean and lube the assembly. I show how to correctly build up the spark advancer and where the alignment marks are located the following post at the link below so you can always assemble it right the first time and avoid this problem altogether.

CT90 Spark Advancer Assembly Build-Up

Step 4 – Is the wire leading to the points assembly correctly installed so that it does not ground out to the frame of the points assembly?

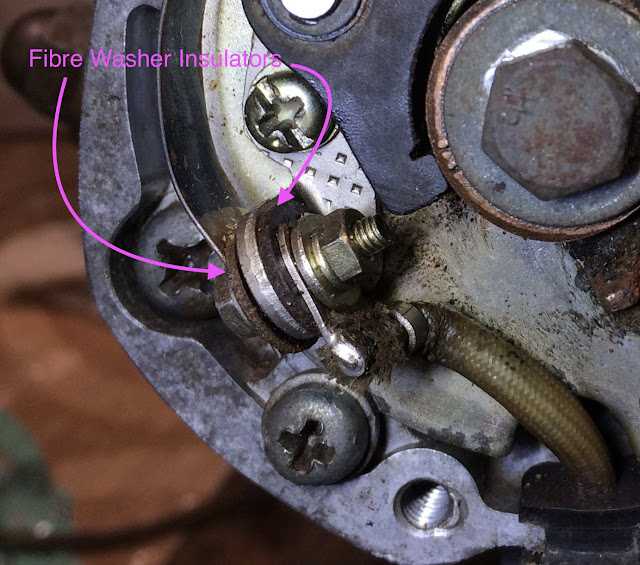

There is one important design detail that is sometimes missed and that has to do with correctly attaching the wire to the points assembly so that it is electrically isolated (not touching) the metal frame of the points assembly. If assembled correctly there are three fiber washers that prevent the wire from contacting the frame.

The picture below shows all of the fiber washers along with the small bolt and nut that are used to attach the wire leading to the points assembly.

There are two large fiber washers and one small one where the small one is installed in the opening in the frame as shown below which is important in preventing the bolt from contacting the frame.

Here are all the washers installed.

And with the wire correctly attached to the points.

Another detail to look at is to make sure that the fitting at the end of the wire that attaches to the points assembly that is shown in the picture above isn't oriented so that it comes in contact with the cover when it is installed which would result in the wire always being grounded.

Step 5 – Clean, check the contact faces, and gap your points

For your points to function correctly the faces of the contacts on the points have to be flat, smooth and clean before you set the gap. If the face of the contacts look questionable then they should be filed or drag some fine emery cloth between the contacts to clean up the faces. For points to operate correctly they need to have a clean separation to ensure the field in the coil collapses quickly to produce the best spark. If there is crud/oil in and around the contacts you won’t have a clean break electrically so use some spray contact cleaner to make sure your points are nice and clean.

I have outlined the steps to gap your points in the post at the link below on the basic steps to adjust your timing.

The Basic Sequence and Process to Set or Adjust your CT90 Timing

Another thing to watch out for here is that it is possible to accidentally install the wire attached to your points so that the terminal attached to the end of the wire is rotated outwards and can come into contact with the cover when it is installed which will ground the wire and prevent the bike from starting. This can be a frustrating item because you’ll remove the cover because the points seem to be the issue, but with the cover off everything checks out fine and then you reinstall the cover and now the bike won’t start and you repeat this sequence until you hopefully figure it out. Make sure the end of the wire is tucked in nice and tight s it won’t contact the cover when it is installed.

Step 6 – Adjust your timing

With this step just set your timing and I have instructions on how to do this in a post at the link below.

The Basic Sequence and Process to Set or Adjust your CT90 Timing

The one thing to watch out for here is that sometimes with bikes that have been built up with a collection of parts from different bikes the fit between the plate the points are mounted to and the recess in the housing it rotates in when you adjust the timing, may not be a nice snug fit. If the fit is too loose then when you set the timing by rotating the plate you end up changing the gap in the points because the plate moves radially ever so slightly. This can be a frustrating problem that may not be readily apparent. In the end you usually need a new housing or plate.

Step 7 – You have a fully charged battery installed

CT90’s require power from a battery to charge the coil and produce a spark. If you have a good battery installed make sure the ground wire attached to the frame and that everything is clean at that joint so you have a nice solid ground. On the power leads from the battery make sure those connections are clean and tight and that you have a good fuse in the fuse holder.

Step 8 – Make sure you turned the ignition key to “on”

I won’t elaborate any further except to say that I have first hand experience that it can happen…

Step 9 – Ensure the spark plug cap has a good connection to the end of the spark plug wire.

One of the common areas where there can be a problem on old CT90’s is with the connection between the spark plug cap and cable. This area can see a lot of heat and sometimes the spark plug cable can become stiff and hard. If your cable is long enough, unscrew the spark plug cap from the cable and then cut off a ¼ to ½ inch of cable. Then reinstall the spark plug cap by screwing it on and you now should have a good clean and tight connection between the threaded probe in the cap with the conductive core of the cable.

Step 10 – You have a good spark verses a crappy spark

It takes a good spark to start an engine, so just because you see some sort of spark at the electrode on the plug, it may not be good enough. Sometimes a used plug with get a fine film that has contaminates that are conductive and while you see a spark its not always across the gap of the plug and won't reliably ignite the fuel mixture in the cylinder.

Whenever I have a bike that is hard starting I always put in a new plug if I have one, and in many cases it solves the problem. If you don’t have a new plug handy you can heat up the electrode end of the plug with a propane torch (and don’t be shy here) and burn off anything that shouldn't be there.

Step 11 – Upgrade your rectifier

On any CT90 I pick up one of the first things I do is upgrade the rectifier. This is an easy change to do and addresses a variety of things that can cause problems. So whether it’s a problem or not with your bike, my recommendation is up grade your rectifier, as you will be glad you did.

I have a post on how you can do this yourself and some sources if you prefer to just buy and upgraded rectifier at the following link:

CT90 Rectifier Upgrade

If you don’t want to upgrade your rectifier, but want to check to see if your current rectifier is ok, here is a link to a post I made on how to test your rectifier:

How to Test Your CT90 Rectifier

Step 12 – Checking your coil and condenser

CT90 coils are very reliable and generally are not the cause for a hard starting CT90. The plug wire leading from the coil to the plug can have issues. If you suspect your coil and or condenser may have issues they are fairly simple devices to test.

Here is a link to a post I did on how to test your coil:

Basic CT90 Ignition Coil Check

And here is a link to a post I did on how to test your condenser:

Basic Test of a CT90 Condenser

Step 13 – Checking for a spark

At this point in the process if you have checked and made sure everything in all of the previous steps was good, your CT90 should produce a spark. If you find that when you have your plug removed but plugged into the cable from the coil and touching the head, with the key on, a good battery installed and all the electric connections have been checked, that you still don’t get a spark when you kick the bike over then here is a simple way to help you isolate the problem.

Disconnect the wire coming from the points assembly where it attaches to the main wire harness and then get a length of wire that has a short length of insulation stripped from each end and then take one end and insert it into the female connector for the points on the main wire harness. Now with the key turned on like you were going to start the bike, touch the free end of the wire to the case of the engine or any other good ground for a second or two and then remove the end of the wire from where you had it grounded. The moment you remove the wire from the point where you had it grounded you should see a spark at the spark plug. If you now do get a spark that means your coil, condenser, plug wire and spark plug are all good and you have an issue somewhere within your points assembly or with the wire coming from the points being shorted out where it passes through the opening in the cylinder or the that same wire having an internal break.

If you didn’t get a spark, then there is something wrong with the coil, coil wire, condenser, or spark plug or one of the electrical connections or grounds for these items.

Step 14 – Did you turn on the fuel?

With the first 13 steps completed and you now get a good strong clean spark, but with the plug installed the engine doesn't fire its time to look at the fuel system. The first step here is to make sure you actually turned the lever on the carb to "on" or "reserve" so that fuel can get from the tank (there is gas in your tank?) to the carb.

Step 15 – Use ethanol free fuel

I have switched over to using ethanol free fuel in my bikes, especially if they will be setting unused for a period of time. I have repeated had issues with my idle jet getting gummed up when I was using fuel with 10% ethanol and had let my bikes sit for a period of time and since switching over to ethanol free fuel those problems have gone away. When you are working on a bike that is hard to start its nice to eliminate anything that could be a possible cause a problem and using ethanol free fuel helps eliminate some fuel related issues.

You can find sources of ethanol free fuel in you area at the link below:

Ethanol Free Gas

Step 16 – Are you using filters on the fuel lines coming from your gas tank?

All CT90 bikes are old, and most have had at least some issue with rust in the gas tank and the idle jet on the CT90 is so small that it takes next to nothing to clog it up which will keep the bike from starting no matter how hard and long you kick it over.

Do yourself a favor and get some in-line fuel filters, as it will eliminate problems in the future.

Step 17 – Initial carb adjustment

If you just picked up a new CT90 that doesn’t run and you don’t have much experience with the CT90 carb, the link below will take you to a post I did where I included a table with initial settings for the two screws you can adjust, so that your carb will be in the ballpark of what should allow your bike to start up.

Adjusting and Jetting a CT90 Carb

Step 18 - Are you getting gas?

The one area where CT90’s are not very robust in my opinion is with the size of idle jet used. If there is any sort of crud no matter how small, you are just about guaranteed that your idle jet will clog and prevent your bike from starting. If your hard starting issues seem to be carb related it always pays to completely disassemble the carb, clean every part and passage with a good carb cleaner like Berryman B-12 Chemtool (and try and find the non-VOC compliant if it is available in your state, its just better) and then blow out the passages with compressed air.

If your hesitant to pull your carb apart as your not sure you can get it back together, I included the link below to a post I made on how to reassemble a typical CT90 carb.

Step by Step Instructions for the Reassembly of a Basic Two Screw CT90 Carburetor

It’s always nice to get a rebuild kit when you take apart a carb so you have new gaskets, but sometimes you’ll find you can reuse the gaskets if they haven’t become too old and hard. If you’re trying to reuse your idle and main jet, but they are clogged with varnish and the carb cleaner wouldn’t clean them out, you can try using a propane torch and that will usually burn out whatever is clogging the jet.

If you do take apart your carb it’s always a good idea to recheck the float height as an incorrectly adjusted float can lead to issues caused by having too much or not enough gas in the bowl of the carb. I have instructions on how to do that adjustment in the link I shared above.

Another common cause for a CT90 to not get gas is if the vents on the gas cap of the fuel tank are clogged. What happens when this is the problem is that the bike starts just fine but after a short period of time the engine dies because gas can't flow to the carb because air isn't making it in to the gas tank and a vacuum is created that prevents the gravity feed fuel from flowing. This is not always an easy issue to catch as the bike will start fine and run for a short bit, but when it dies the rider starts to try and figure out what is wrong and during that time air seeps back in through clogged vent in the gas cap, so the next time the person tries to start the bike, it fires right up. If you think you have this problem, just loosen the gas cap so its covering the opening, but not all the way twisted down. If this solves your problem get a new gas cap or try cleaning the old one so the vent holes are clear and functioning.

Step 19 – Are you getting too much gas?

If your lucky and your bike starts just after you have rebuilt your carb, but then becomes very hard to impossible to start later on that is a potential sign that the float in you carb is cracked and leaking which will allow your bike to become flooded. This is not always easy to detect as when you take apart the carb to figure out what is wrong and the float is setting on your bench all the gas that seeped into the float will evaporate out and when you reassemble the carb your bike will start initially, but then again become hard starting. The cracks in the brass floats are not that obvious and are usually very fine hairline cracks. When in doubt just get a new float.

The other item that can cause your bike to flood is having a worn float valve. When you disassemble your carb inspect the float valve components and if you see a ring around the pointed end where it mates to the seat then it’s time to replace the float valve. These are almost always included in a carb rebuild kit, but can be bought separately.

Step 20 – Some additional comments

There is a temptation to use starting fluid to get a bike to start and I have done it myself, but in general I would recommended to avoid using it or use it very sparingly. Starting fluid has the risk of stripping out the oil film in your cylinder, which is undesirable. If you do use it and your bike starts and runs for a few seconds, that’s great because you now know that you have adequate compression, your timing is good, and you have a decent spark. Beyond that, continuing to try and get you’re bike running using starting fluid won’t fix what is keeping your bike from running and may potentially result in damage to your cylinder. If your bike starts using starting fluid, but doesn’t run otherwise you have a fuel problem and need to focus on fixing what is wrong with your carb.

Another use for starting fluid is to check for leaks between the carb and where it bolts to the intake manifold and between where the intake manifold attaches to the cylinder head. Sometimes people find they can get their bike to start with the choke on, but it dies anytime they try and remove the choke. When you use your choke it has the effect of enriching the mixture going to the cylinder. If a bike will only run with the choke on that usually means there is an air leak between the carb and cylinder head which results in an overly lean mixture without the choke on. If you suspect this condition, while the choke is on and the engine is running, spray starting fluid at each of the joints on the intake manifold and if the engine rpm’s increase it means you have an air leak at the joint where the starting fluid caused an increase in rpm’s.

If your bike can just start and idle but backfires through the carb when you give it any throttle, then that is another indication that you are running to lean and there is a good chance your main jet is partially clogged. If you close the choke and the throttle response seems to get better that is further confirmation your main jet or emulsion tube is clogged.

I hope the information I shared above is helpful in getting your hard starting CT90 back up and running.

Helpful Links (Shop Manuals, Wire Diagram, Model Information, etc.)

Link to page with listing of CT90 parts available on Amazon

thanks so much for your time and experience!

ReplyDelete