Anyone who ever buys a CT90 will at some point in owning the bike have to disassemble, clean and reassembly a CT90 carburetor. The focus of this post is really just on the reassembly of the carburetor. So after you have disassembled and cleaned all of the parts of your carb and picked up a new gasket set (or reused your old gaskets) you're ready to reassemble your carb. The terminology I use in my descriptions below is my own and may not be exactly the same as what is called out in a Honda manual, but I hope it is clear enough for you to understand which parts I am working with.

Link to related Posts:

Adjusting and Jetting a CT90 Carb

With respect to a new gasket set, I generally wait until I have disassembled the carburetor before I make the decision to buy a new gasket set. I have found that most of the time the condition of the old gaskets are just fine and I'll apply a little

RuGLYDE to freshen up the elastomeric parts and seals and just really make sure all of the jets are clean and I'm good to go. I have rebuilt a number of carbs over the years so I also have a small stash of carb parts to draw from if needed, but the cost of a carb rebuild kit is almost as much as an aftermarket CT90 carb, so if I can avoid buying a rebuild kit I do, and 99% of the time the carb rebuilt with the previous seals and jets comes out just fine. If you do think you need a rebuild kit, I have a table in a

post I did on Adjusting and Jetting a CT90 Carb that includes kit numbers and links to where you can purchase the kit.

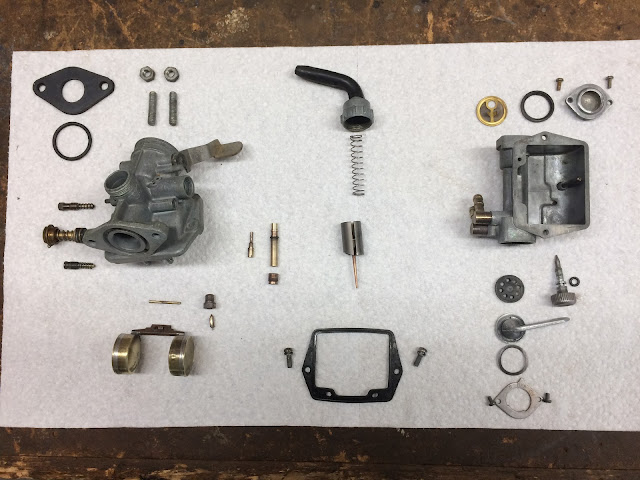

Here is an overall shot of all the detail parts that go into a basic two screw CT90 carb.

I'll usually reassemble the lower bowl section of the carb first starting with the needle valve screw for the bowl drain.

I'll assemble the o-ring into the groove on the screw making sure to apply some sort of lubricant or RuGLYDE to the o-ring so it easy to work it down the length of the screw and into it's groove. I'll also add a tiny amount of grease to the treads on the screw before I install it into the lower bowl section of the carb. The grease is an important step as these screws can become really hard to remove if any corrosion or crud builds up between the screw and the housing which can lead to the screw shearing off if your not careful (based on first hand experience), so its worth the time to apply a little grease.

I'll next assemble the fuel selector section of the lower carb bowl, by first installing the flat elastomeric disc that is the seal for the fuel select lever. If you are reusing the sealing disc and some of the holes have issues/damage from when they were previously installed over the three holes that the fuel flows through, just rotate the disc so a fresh portion of the disc is over holes the fuel will flow through and the less desirable section is over the locator pins that position the disc. The key thing is to make sure the flat surfaces of the disc are clean as that is the surface that will provide the seal when all is said and done.

I'll next install the fuel select lever and I always check that the surface of the lever that mates with the elastomeric disc is perfectly clean and smooth and that the kidney shaped slot that the fuel will travel through is also perfectly clean.

I'll assemble the lever into the recess with the elastomeric disc.

I'll next assemble the spring that looks like a warped flat ring making sure to place the curved side of the spring against the surface of the lever. This is important as the surface of the spring will slide on the lever when it is moved to select the different fuel positions (off, reserve, and on) and to prevent wear at this interface you want the smooth curved surface of the spring against the mating lever surface as shown in the picture below.

I'll next install the thin plate that holds the lever assembly to the lower carb bowl housing. The only thing to remember here is that the lettering on the plate faces outward and the pointed feature on the plate faces up or towards the open section of the bowl.

Another thing to keep in mind is that the shortest set of two screws are used to install this plate while the longer set of screws are used to the cover that we will install in the next step.

Here is the final installation of the lever.

I'll next install the fuel filter/screen portion of the lower carb bowl assembly.

First I'll simply lay fuel filter screen in the recess making sure to align the hole in the filter screen to the mating feature on the carb housing and making sure the two little fingers that you picked up the screen with are facing outward.

I always use fuel filters on each of the fuel lines coming from the fuel tank to the carb, so I really don't care if the fuel screen has holes in it as long as it is clean. If you're using external fuel filters the screen is still required so that the seal for the cover has something to compress against, otherwise there may not be enough squeeze on the o-ring for it to seal the cover. I'll next install the seal which sometimes can be swollen if it has recently been exposed to fuel, but just squeeze it in if that is the case.

With the seal in place install the small cast cover with the two longer screws and the lower carb bowl assembly is complete and its time to work on the upper half of the carb.

Starting with a cleaned upper half of the carb I will first install the altitude compensation valve.

When I take apart a carb and clean it I generally don't disassemble the altitude compensation valve unless something is missing or damaged. The valves are generally clean as most people never use this feature on the carb. Before reinstalling the altitude compensation valve I will apply a lubricant to the o-ring and face seal.

I'll then install the altitude compensation valve and just snug it up with a little torque.

Once installed, I'll make sure the valve operates correctly and stays in the detested position when pulled out to the position that kicks in the altitude compensation feature.

I'll next install the idle screw/spring and air mixture screw/spring into their respective holes in the upper housing.

I'll install each screw/spring assembly and then screw it in until it just lightly seats and then unscrew it two full turns which should be an acceptable point to be able to get the CT started once its back on the bike.

With that completed I turn my attention next to full bowl area of the upper housing.

I'll next install the emulsion tube by first making sure the o-ring is installed in its groove and lightly lubricated and then I'll insert the emulsion tube into the large hole at the center of the housing.

You need to be gentle with the next step, but with the housing upside down resting on a firm surface (your workbench), take a punch or something similar that has a diameter close to the diameter of the end of the emulsion tube it will be contacting and then very lightly tap or push the emulsion tube into its final position.

Next install the main jet by screwing it in to the hole you just installed the emulsion tube into until it light seats.

Next I'll install the idle jet making sure to screw it in until it lightly seats.

I'll next turn my attention to installing the float valve and float into the upper housing. The float valve has three parts, the brass valve seat, the sealing washer and the needle portion of the valve.

I'll place the sealing washer over the brass valve seat and then screw those parts into the housing.

I'll screw the valve seat in with the appropriate wrench until it is lightly seated and then I will install the needle portion of the valve by dropping it into the center opening of the valve seat.

I'll next install and adjust the float assembly by first starting the brass pin the float will rotate on into either one of the two posts it installs into.

I'll next position the float between the two posts making sure the adjustment tab on the float is facing down towards the exposed end of the needle of the float valve. While installing and adjusting the float I try and go easy on the float assembly so I don't ever cause it to apply any force on the needle of the float valve which could potentially damage the needle or valve seat.

And then push the pin through the mating feature of the float until it is fully seated in the opposite post.

If your pin slides in easy with very little force thats great as the pin is captured by a recessed feature in the lower bowl housing so it can't ever back out once the carb is fully assembled. If on the other had your pin is more difficult to install, either remove it and clean with some steel wool or very fine emory cloth to see if the fit will loosen up, but if you do have to end up tapping the pin to install it make sure to tap lightly and try and support the far post with a socket or something else so you don't accidentally break it off.

The next step is to adjust the height of the float before we assemble the upper and lower halves of the carb together. You can buy tools for helping measure the float height, but I use a dial caliper when I am setting the float height.

On a two screw CT90 carb the float height should be set at 20 mm or .787 inches (a older four screw CT90/CT200 carb should be set at 23 mm or .905 inches). DrATV has two useful items on its tech page that have additional information on adjusting your float -

Link 1,

Link 2. The key thing to remember when you are checking and adjusting your float height is that you really want to minimize applying any force on the needle of the float valve so you won't damage the needle or valve seat.

I adjust and lock down my caliper to the correct dimension and then check the float height from the gasket seating surface on the carb housing to the highest point on the diameter of the float. When you are checking the float height you should have the body of the carb at an angle like is shown in the DrATV links I provided above and the goal is to only have a very small amount of force being applied by the tab on the float that rests on the float valve needle.

The following pictures are not at the desired angle that you should check the float height at, but to make taking the pictures easier I am showing how the caliper should rest on the float and flange of the upper carb housing when you are checking the float height.

When you have the float height adjusted correctly the float should be the same when you check the height of both the left and right portions of the float assembly.

If you do have to adjust the float height you'll have to bend the small tab on the float assembly that mates with the end of the needle of the float valve. The key point here is that when you do go to bend the small tab you need to make sure that you first lift up on the float assembly and then make sure no force is ever applied to the needle of the flat valve while you are adjusting the tab in or out.

With the float height adjusted then next step is to install the gasket that goes between the upper and lower housings and then assemble them together.

The gasket has four holes of which the two that are furthest apart are for the screws that hold the two housings together and the other two holes are to allow fuel to pass from the lower bowl up and to the float valve. Only one of these holes is actually used at a time, but having two holes makes it so you can't screw up when installing the gasket.

The next step is to simply assemble to two housings together.

And install the two screws that hold the upper and lower housings together.

Next I'll assemble the slide assembly which is made up from the four parts in the picture below.

The first step is to assemble the circlip to the needle. The starting position is in the center of the five grooves which provides the nominal adjustment between the maximum richness setting and the most lean setting. This adjustment controls the fuel/air mixture when you are operating the CT90 above idle.

To be clear about where to install the circlip for the most lean setting if that is desired, the picture below is of the circlip installed in that position.

And the picture below is of where to install the circlip for the most rich position if that is what you are looking for.

Once you have determined where you want to install the circlip on the needle, you then take that subassembly and drop it in to the slide assembly and make sure it rests at the bottom of the cavity in the recess for the circlip.

Next you install the "M" shaped retention clip into the slide making sure the opening in the middle of the "M" is facing the slot the runs the full length of the slide. The opening at the end of the slide where the retaining clip is installed is beveled to help you get it started and then make sure to slide it all the way to the bottom of the cavity where friction between the clip and the bore in the slide will retain it in that position and prevent the needle subassembly from moving.

While the slide will have to be removed to hook it up the throttle cable once the carb is mounted on the engine, I'll still go through the steps of assembling it to the carb.

Once the slide is assembled it is dropped down into the opening at the top of the carb aligning the slot on the side of the slide with the pin that is inside of the opening and opposite the idle adjustment screw.

With the slide installed the slide spring can then be installed.

Before installing the cap that captures the spring and slide you should make sure that there is a gasket in the cap for where it mates to the rim on the upper carb housing. This gasket isn't always included it carb rebuild kits and I have bikes where I don't have this gasket installed that run just fine, but it is better if you have it as the fewer air leaks you have the better your carb will perform.

Install the cap.

If you don't have studs installed that will be used to mount the carb to the intake manifold, that is the next step in the process. I sometimes apply red loctite to the portion of the stud that screws into the carb so that the studs won't tend to unscrew when removing the carb from the bike, but this sometimes can be a catch-22 if the nut you use to hold the carb to the intake manifold become corroded, you can potentially rip the threads out of the carb flange (I have first hand experience at this...) so you may or may not want to apply loctite, but its what I do and I make sure the nuts I use to attach the carb spin freely on these studs and I'll always apply a little lube to help ensure this.

The assembly of the carb is basically complete at this point, but I generally install the next few parts so the carb is ready to go when I go to install it on one of my CT90's.

I'll install the o-ring that goes in the groove of the flange that mates to the intake manifold

I'll next install the plastic thermal isolator that goes in-between the carb and the intake manifold that helps prevent heat from the engine from finding its way back to the carb.

And then loosely install the two mounting nuts just to keep everything together prior to installing the carb.

And with that last step the carb is complete assembled and ready to be installed.

I hope the above information was helpful with your efforts to rebuild your own CT90 carburetor.

Helpful Links (Shop Manuals, Wire Diagram, Model Information, etc.)

absolutely excellent . a way better than any you tube videos. your pictures are perfect. the main reason it is so much better than You Tube videos on the same subject matter it is much easier to go back and work at your pace. thank you so much and happy trails !!

ReplyDeleteAggreed Very nicely done!

DeleteVery well done. You covered everything a person could ask for, with such attention to details. This is better than having a cryptic manual to follow,

ReplyDeleteVery nice work, Thank you

Tom

Great procedure thanks! I have a 1970 CT70 with almost the same carb but does not have the altitude compensation valve. One question on the brass inlet fuel barbs. Mine just push in and can swivel. Looks like i have a slow gas drip coming out one or both. Should those brass inlets fit in real tight and is there supposed to be a small rubber gasket inside the carb inlet so no leaking?

ReplyDeleteExcellent procedure thanks! I have a 1970 CT70 with almost the same carb. Question: the brass fuel inlet barbs on mine just push in a swivel. Looks like I have small gas drip coming from one or both. Should these brass fittings fit in real tight so no leaking and should they have an O-ring gasket inside to prevent leaks?

ReplyDeleteThanks.

Thanks, great step by step. One question for the next step, what is needed to seal the plastic thermal isolator to the intake? Just dry and clean, or some sort of sealer between the contact faces?

ReplyDeleteDoes anyone know where I can get the push fit brass inlets, I broke one and I cant find any. The picture 4a23 shows the two brass inlets on the lower right side

ReplyDeleteExcellent instructions, Great Pics. You knocked it out of the park on this. Thank You Very Much.

ReplyDeleteGreat step by step instructions.

ReplyDeleteDo you know if this will also work for the other style of CT90 carb that has the 4 screws around the perimeter instead of 2?

Dustin

Awesome! Sooo helpful. Thank you for laying this out step by step and all the links!

ReplyDelete