In this post I want to share a very simple and inexpensive way to build a clutch holding tool with plumbers tape.

Update: I now make and sell a clutch holding tool that also can be used to loosen your headset nuts and more info is available here at a post I made at this link.

There is a good chance with every Honda CT90 that at some point in its life you are going to have to rebuild the clutch. Rebuilding your clutch isn't really all that difficult of a task to do, and it has the added benefit of allowing you access to clean your oil screen and also to check to make sure your shift drum stopper hasn't developed any cracks (see:

Shift Drum Stopper Replacement When Doing a Clutch Rebuild)

While the overall effort to replace your clutch disks is very straight forward, there are two steps in the process that can be a bit of a pain if you don't have the right tools. The challenging steps are with finding a way to hold the clutch assembly and keep it from rotating while you're loosening or tightening the spanner nut that retains the clutch assembly.

If you do this the way you are supposed to do it, and use the special tool to hold the clutch assembly and a special tool to engage the spanner nut, the task is straight forward and easy. While the task becomes easy, the tools do cost money and if your like me (I'm cheap...) you look for ways around having to buy a special tool you won't use all that often.

The special spanner nut tool is a relatively inexpensive tool and can be picked up on eBay for less then $7.00. I did a short review of the spanner nut tool I use at the

following link on the tool I purchased off of eBay.

The bigger issue is the clutch holding tool as they are not as readily available and they can be expensive. If money isn't an issue you can just buy a tool

like this one from DrATV for a little under $50.00.

I have done a few Honda CT90 clutch rebuilds and I have always in the end been able to use strap wrenches, clamps, etc. and have been successful at holding the clutch well enough to loosen/tighten the spanner nut, but most of the time it has been a real pain and a lot more work then it should be. But with a clutch I was doing recently, I think I have come up with a simple approach that works reasonably well and is very cheap.

My latest approach at a clutch holding tool is to use a length of plumbers tape and a number of 1/4 in bolts.

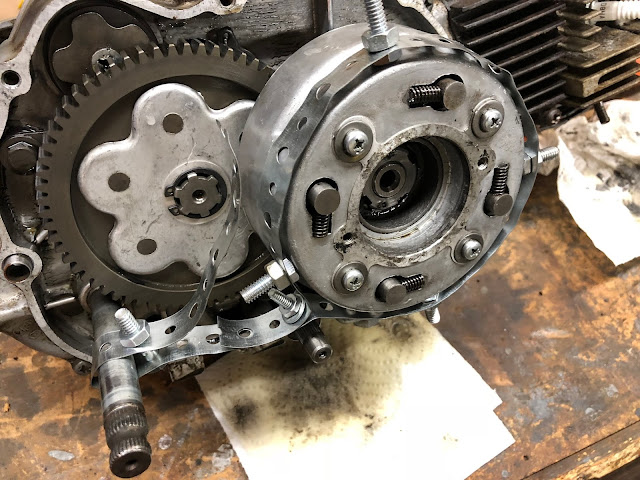

Here is a picture of the tool installed on the clutch I am currently working on.

The concept is pretty simple. You take a length of standard plumbers tape like what you can pick up in the plumbing section of your local hardware store and the install several 1/4 inch bolts around the length of the tape that will go around the clutch assembly with the heads facing the outside diameter of the clutch housing. A fifth bolt is used to close off the loop of tape around the clutch assembly and the holes it goes through are selected so that when this bolt is tightened up the loop around the clutch gets snugged up nice and tight. The remaining tail of plumbers tape it then wrapped around the kick-starter shaft and secured with a bolt.

The idea here is that one or more of the heads of the bolts on the plumbers tape tightly wrapped around the clutch assembly will engage one or more of the four lugs on the outside diameter of the clutch housing while you are loosening or tightening the spanner nut.

I did find in use that sometimes the heads of the bolts would want to slide off the clutch housing as torque was applied to the spanner nut, but I put a single clamp on as shown in the picture below and that took care of that problem.

Here is a picture of the plumbers tape tool just sitting on my bench.

Another option would be to just by a tool and I now make and sell the tool below with more information on

how to get one at the post I made here at this link.

I hope this post was helpful and good luck with your next Honda CT90 clutch rebuild!

Helpful Links (Shop Manuals, Wire Diagram, Model Information, etc.)

Link to page with listing of CT90 parts available on Amazon

BUY THIS TOOL ! .

ReplyDeleteI'm a Honda Moto Mechanic and I bought and use this fine tool a lot .

No downsides, it reduces time and aggravation .

-Nate